PROJECT SUMMARY

Dynamo designed a greenfield substation and medium voltage distribution for a canola processing facility near Yorkton, SK.

PROJECT SUMMARY

SECTOR:

Food

CLIENT:

Saputo Inc.

DURATION OF PROJECT:

4 Months

PROJECT SUMMARY:

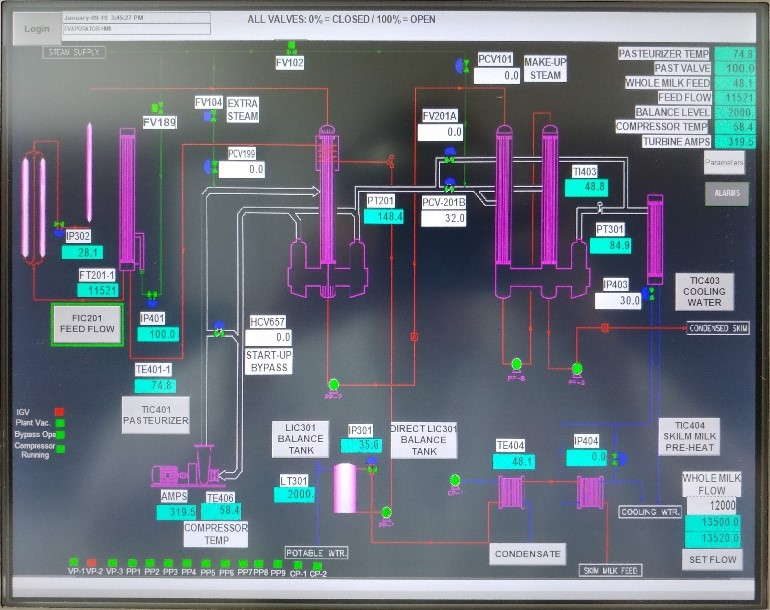

Dynamo provided design, programming, and installation services to migrate Saputo Inc.’s skim milk evaporator control system to a single Programmable Logic Controller (PLC) with a touch screen Human Machine Interface (HMI).

The skim milk evaporator’s process control consisted of a variety of different, independent process controllers used to regulate or monitor parts of the process. Each of these controllers were removed from service and their analog and digital signals were wired to a cabinet with new Allen-Bradley FlexIO remote input and output modules. After the old controllers were removed, a new Allen-Bradley integrated display was mounted in its place and networked to the FactoryTalk Server.

Saputo Inc.'s existing ControlLogix processor was programmed to perform all original control functionality and allow an operator to monitor and control the progress through an HMI. A custom display screen was created for the specific process.

The migrated control system and HMI were commissioned by Dynamo personnel by performing end-to-end field testing of each instrument and running through the start-up, shut-down, and clean-in-place functions of the process.

Recent Posts

Dynamo designed a greenfield substation and medium voltage distribution for a canola processing facility near Yorkton, SK.

Dynamo was retained to complete the decommissioning and disposal of one (1) 20 MVA transformer, BU-410-TX-1 and one (1) high voltage oil circuit breaker, BU-410-TX-1-OCB at the Bethune Station and one (1) 20 MVA transformer, ZP-420-TX-2 at the Loreburn Station.

Dynamo was retained to fabricate, ship, and install a 9.6 m x 4.5 m control building for the Grenfell Substation. Drawings were supplied by Dynamo based on a preliminary design provided by SaskPower.