PROJECT SUMMARY

Hoist drive upgrades at the Nutrien Allan Potash Mine had caused undesirable harmonic effects that resulted in vibration and damage to the existing production hoist transformers, eventually leading to failure...

PROJECT SUMMARY

SECTOR:

Agriculture

CLIENT:

Lucky Lake Irrigation District

DURATION OF PROJECT:

6 Days

PROJECT SUMMARY:

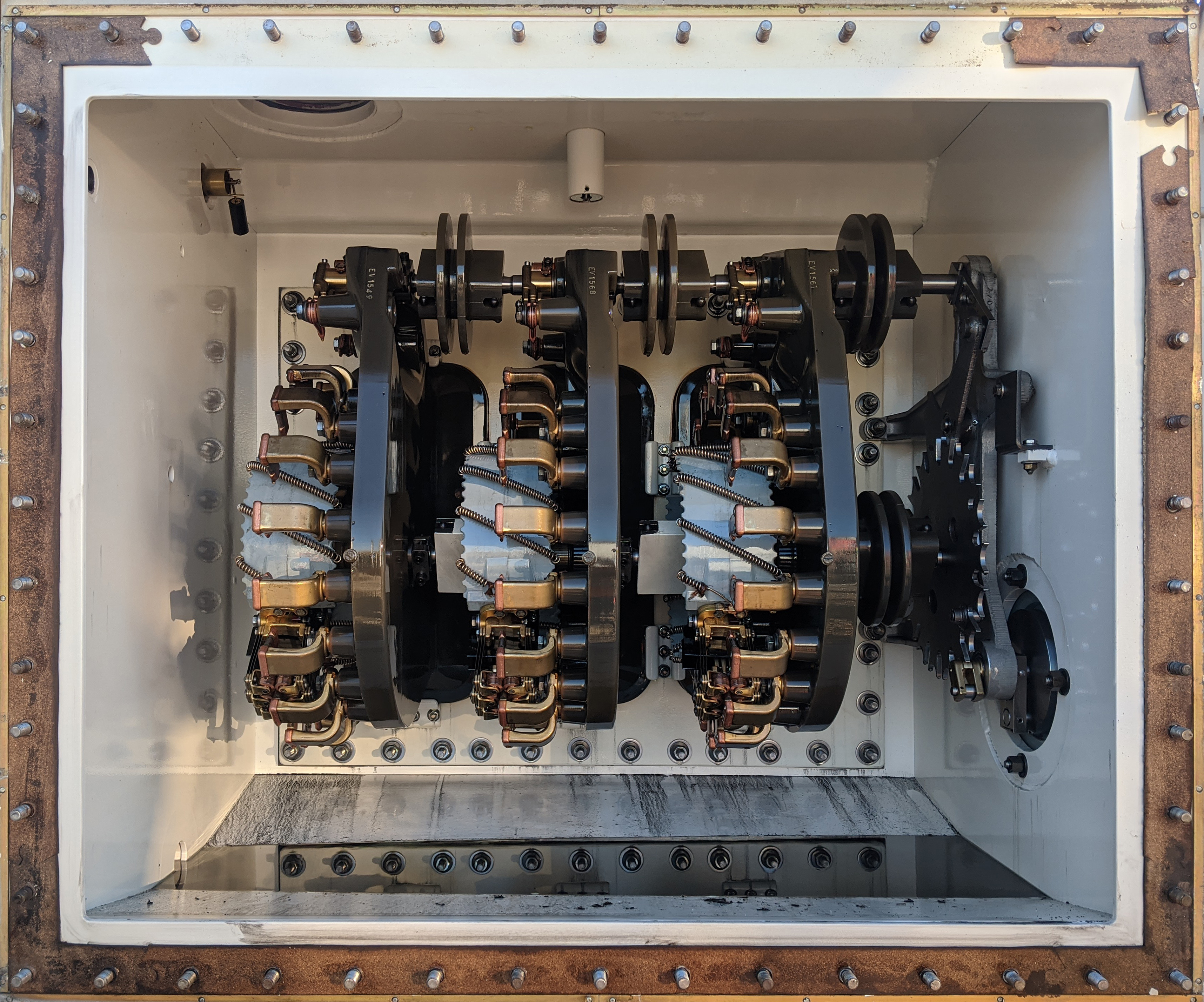

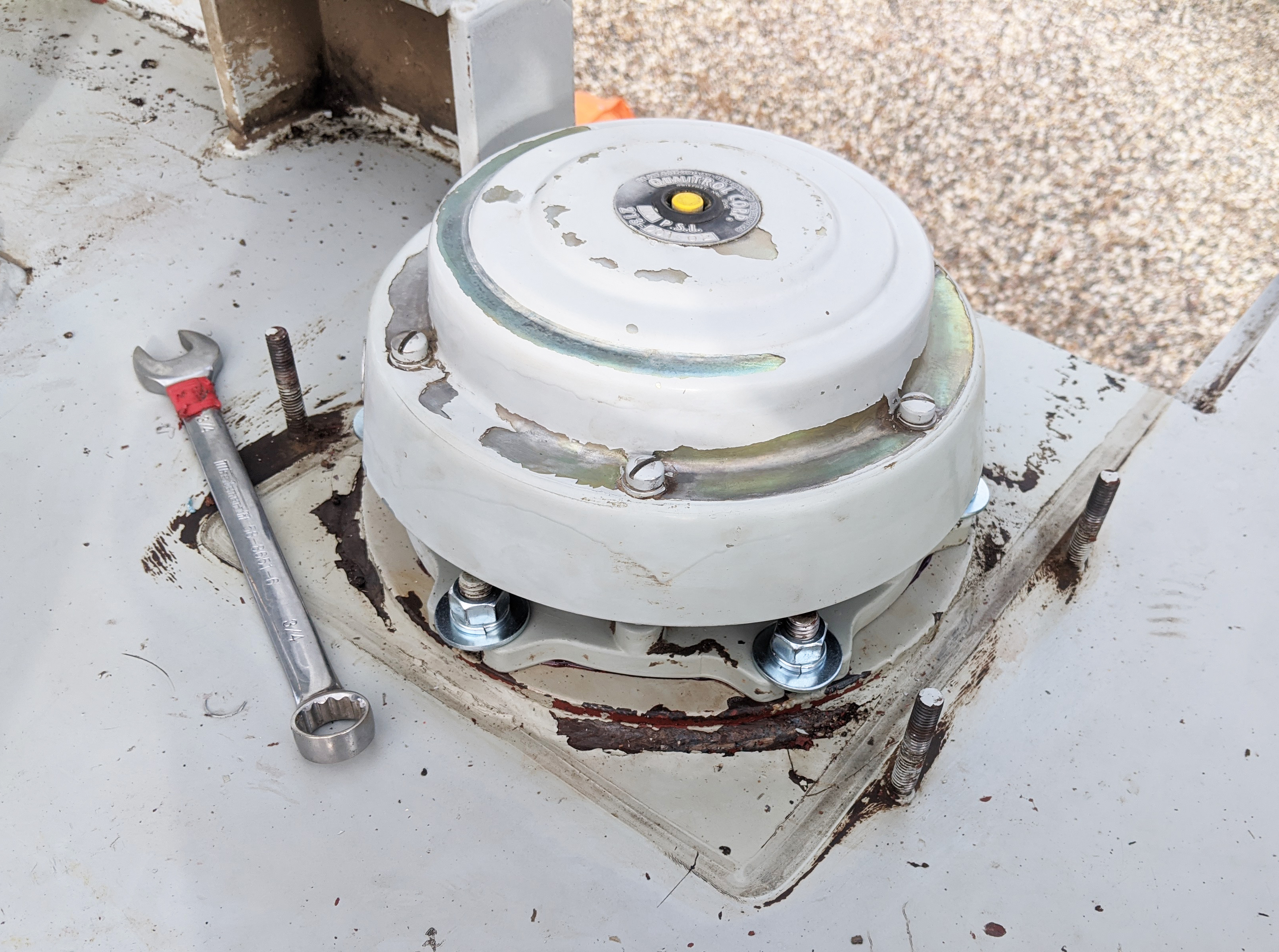

The 72 kV: 4.16 kV transformer at the Luck Lake Irrigation District (LLID) Pumphouse has developed several moderate leaks over its service life. The transformer was manufactured in 1988, and since that time no refurbishment or leak repairs had been undertaken. Several gasketed and sealed components developed leaks causing a minor loss of oil (found 300 liters below nominal) and potential environmental concerns to the surrounding area and waterbody. The unit is filled with mineral oil and has been confirmed to have 0 ppm PCB content. Dynamo was retained to repair leaking components and perform oil processing on the unit.

Over a six (6) day period, the unit was drained and repairs were made to all leaking components, including: bushing gaskets, hatch gaskets, piping and Victaulic fittings, valve stems, valve packing, valve seats, and flange gaskets.

A 50-ton mobile crane was used to remove bushings and radiators. A 30,000-liter stainless steel tanker was used to store oil for the duration of work and positive pressure maintained with a mobile dry-air compressor (dew-point -70°C).

A total of thirty-six (36) gasket seals were replaced, with twenty-three (23) valve seats, seals, and piping repairs made.

After all the gasket work, the transformer was evacuated to 0.31 mmHg of vacuum and vacuum filled. The unit was topped-up and fully tested prior to re-energization. Oil was processed to approximately five (5) total passes, 120,000 liters of total processing volume.

Recent Posts

Hoist drive upgrades at the Nutrien Allan Potash Mine had caused undesirable harmonic effects that resulted in vibration and damage to the existing production hoist transformers, eventually leading to failure...

Dynamo executed the electrical and civil work for the brownfield 72 kV station at the QE6 (Q3N) In-Line Breaker Substation located near Saskatoon, SK...

Dynamo was contracted to fabricate, ship, and install a

16 m x 7.3 m switchgear building for the Parkridge Station in Regina, SK. The project was guided by a complete set of sealed drawings developed by Dynamo based on preliminary designs from SaskPower..